This is an example of prototyping and small-volume production at low cost by using small equipment rather than installing fully automated equipment from the beginning, for example, when the production volume is uncertain or problems in the production process are to be resolved. We offer a comprehensive proposal from equipment to clean booths.

Advantages

- Layout can be easily changed to accommodate changes in process conditions and production volume.

- Low initial installation cost due to combination of general-purpose standard equipment.

- Similarly, general-purpose products allow for the start-up of facilities in a short period of time.

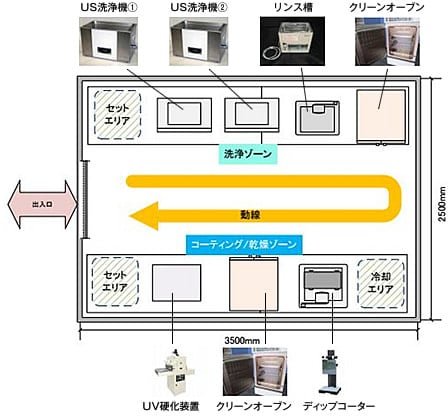

Layout concept in a clean booth (reference example)

| Purpose | Hard Coat Prototype |

| Flow Case Study | Neutral cleaning → Pure water cleaning → Rinse → Draining and drying → Dipping → Solvent drying → UVcure |

| Identify the operator | 2~3 |

| Footprint | 3,500mm × 2,500mm |

| Delivery time | About 2month |

Washing process (pre process)

- US Cleaning Equipment(for primary use)

- US Cleaning Equipment(for secondary use)

- US Cleaning Equipment(for rinsing)

- Small drying furnace(For draining and drying)

Coating process

- Dip coater for small laboratory use

Dry process(post process)

- Compact drying oven (for solvent drying)

- Desktop UV curing system (wavelength: 365 nm)

Layout examples for prototyping

We can also provide a complete quote. You can also visit our lab to see examples of our work. Please feel free to contact us.

※ Lab tours are available only to end users directly. Please note that we do not allow visitors to tour the lab directly.