From Wet to Dry Surface after Dip Coating

Immediately after dip coating, the surface of a coated material is wet. It is necessary to speed up the curing process after dip coating to prevent dripping and contamination.

We propose jigs with both heat resistance and UV resistance for not only equipment for mass production, but also for testing and research equipment, so that after dip coating, a coated material can be dried without removing it from the jig.

UV curing treatment and hot-air drying treatment each have their own merits and demerits, which are taken into consideration when selecting a coating liquid.

So as to avoid various problems such as contamination, cracks, and cloudiness on the surface of a coated material, we provide equipment suitable for UV curing and hot-air drying treatment to meet your needs.

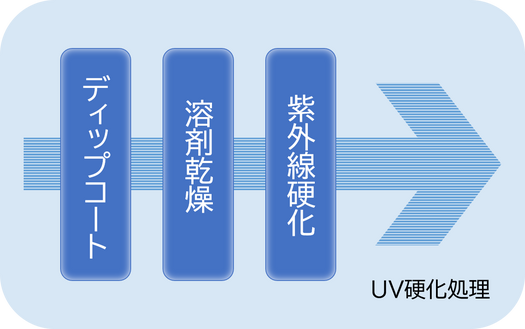

Example of processing flow

UV Curing

In recent years, UV curable coating liquid have become popular as they enable shortening the processing time after dip coating. We offer the most suitable system for each coated material and coating liquid, such as required totalized light intensity, stable UV irradiance, and avoidance of influence of heat on a coated material.

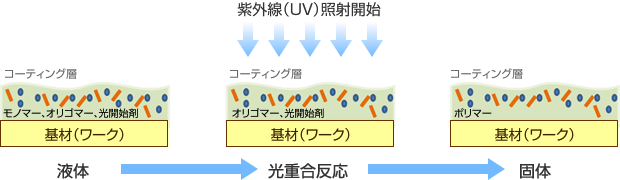

What is UV Curing?

In UV curing, "photopolymerization reaction" within the UV-cured resin causes a liquid to change into a solid.

UV-curable resin used in UV curing consist of monomer, oligomer, photo initiator and additive. When UV-curable resin is irradiated with UV light, the photo initiator act on the other constituent substance, causing a liquid to change into a solid.

Features of UV Curing System

Our UV curing technology is expanding from the printing field to high-tech fields such as semiconductor and electronic and optical components as an indispensable process.

Applications of UV curing

Adhering

- Adhering Chip Components

- Adhering of motor magnets

- Adhering glass/lens

- Temporary fixing of lead wires, etc.

Printing

- Marking of electronic components

- Printing on CDs and DVDs

- Printing on molded plastic products

- Printing of stickers and labels

Coating

- Anti-rust coating of metals

- Hard coating of lens

- Coating of wood products

- Hard coating of resin products

Curing

- Sealing of LCD panels

- Curing of repair putty agent

- Main sealing of LCD panels

- Temporary fixing of electronic components

Six features of UV curing

- High productivity. Curing time is only a few seconds.

- Environmentally friendly. No organic solvents are used, avoiding air and water pollution.

- Improved quality. Improved gloss, strength, solvent resistance, abrasion resistance, and contamination resistance.

- Low temperature treatment

- Space saving

- Energy saving

UV Lamp

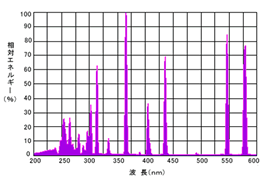

Select UV lamp that match the properties of a coating liquid, adhesive, and UV-curing resin

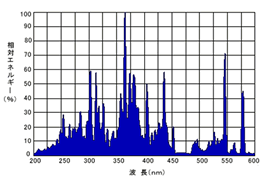

There are two types of UV lamp used for UV curing, high-pressure mercury lamps and metal halide lamps, so use the lamp that matches the properties of a coating liquid, adhesive, and UV-curing resin.

How to Select UV Curing Equipment

Select the required wavelength and lamp

Select according to the properties of a coating liquid, adhesive, and UV curable resin.

- High-pressure mercury lamp

- Metal halide lamps (Fe)

- Metal halide lamps (Ga)

Select the irradiation area

Select the area to be irradiated according to the size of a coated material to be irradiated.

- 80mm

- 125mm

- 250mm

- 375mm

- 500mm

- 750mm

Select the irradiation area image

The effective irradiation width in the direction parallel to a lamp is based on 50 mm, and the effective irradiation width in the direction perpendicular to a lamp depends on the lamp's luminescence length, thus select a lamp with a luminescence length 10% longer than the size of a coated material to be irradiated.

UV rays will be emitted even in areas outside the effective irradiation width, but the intensity of the UV rays will decrease.

Select the lamp output

Select the lamp output according to the intensity of UV rays required for curing.

- 50W / c㎡

- 80W / c㎡

- 120W / c㎡

- 160W / c㎡

- 240W / c㎡

The unit of W / c㎡ is used to express the capacity of lamp by dividing the total input (W) by the luminescence length (cm).

selecting the optional features

Please select the optional features that best suits your needs.

- IR cut filter

- Airflow system for cooling of a coated material

- Shutter system

- Others

Heat cut filter and Airflow system for cooling of a coated material can be used to suppress the temperature rise of a coated material, thereby expanding applications for heat-sensitive materials.

Shutter open/close

When the lamp needs to be turned on and off frequently, a shutter is used to shield the light. Shutter shading prevents short lamp life due to ON/OFF blinking and suppresses the temperature effects of a coated material.