Keywords

Anti Reflection coating

It is used on glass plates, LCD panel surfaces, optical lenses, etc., to prevent light reflection and glare. WET coating methods such as vacuum evaporation, sputtering, or dip coating are used to form a thin film on the surface of the lens or other object by applying, drying, and curing the film.

COP(Cyclo Olefin Polymer)

Cyclo-olefin polymer resin. It has high transparency and low water absorbency, and is used as an optical material.

IR Drying

Infrared ray dryers.A method of drying workpieces after dipping using infrared irradiation equipment.

Layer By Layer

Another name for Alternate Adsorption method.

L-membrane

By gently dropping a small amount of amphiphilic molecules onto a clean water surface, the molecules form a membrane consisting of a single layer of molecules at the water/air interface. These are called Langmuir membranes (or L-membranes, monolayers on the water surface, Langmuir monolayer).

LB Membrane

By moving a solid substrate such as glass up and down through the water surface while keeping the monolayer on the water surface in a solid state, the monolayer is transferred onto the substrate and the resulting film is called a monolayer accumulation film, or Langmuir-Blodgett film (LB film for short).

PMMA(polymethyl methyl methacrylate)

A type of acrylic resin.

PP

Abbreviation for Polypropylene.It is used as a material for jigs and other tools because of its high strength, lack of moisture absorption, and excellent resistance to chemicals (including acids and alkalis).

SS

Abbreviation for Steel for Structure.In the case of dipping equipment, baking coating is used where heat or corrosion resistance is not required.

SUS304

Typical austenitic SUS stainless steel grade.It has excellent corrosion resistance and workability, and is used in a wide range of applications.

UV Ozone Cleaner

Also called "ultraviolet ozone cleaner," "UV cleaning equipment," "UV surface modification equipment," etc., this equipment removes organic matter and modifies the surface of resins, etc., using wavelengths of 184.9 nm and 253.7 nm as its main wavelengths.

UV drying

A method of drying by irradiating a high-pressure mercury vapor lamp, etc. with a main wavelength of 365 nm after coating with UV-curing (ultraviolet light curing) type liquid. Compared to hot air drying, this method requires less time.

UV cure

Another name for UV drying.

Acrylic Resins

An amorphous synthetic resin with high transparency. In particular, transparent solid materials made of poly methyl methacrylate (PMMA) are also called acrylic glass. High transparency and impact resistance.

unloader

A unit that discharges workpieces from the dip coater. ⇔ Loader

ionic bond

A cation that has lost an electron and an anion that has gained an electron are electrically attracted to each other and bond together.

Wet Cleaning

A method of cleaning a coating object using a cleaning solution.

Wet Processes

A method of depositing a film from the liquid phase under atmospheric pressure. Dip coating, spin coating, spray coating, etc. ⇔ Dry process.

Overflows

A method of draining liquid from a dip tank for the purpose of maintaining a constant height of the liquid surface and eliminating contamination.

Chemical bonding

The forces that bind atoms together in a molecule or crystal. They include covalent bonds, ionic bonds, metallic bonds, hydrogen bonds, and van der Waals bonds.

Covalent bonding

A state in which atoms are bound together by shared electrons.

Metallic bonding

Bonds that join metal atoms together to form a metal crystal. In metallic bonds, the atoms are arranged in regular order and the electrons in the outermost shells move freely throughout the crystal.

Alternate adsorption method

A water-based coating method with low environmental impact.

Alternating Layering method

Another name for Alternate Adsorption method.

Titanium oxide

An oxide of titanium, also called titanium dioxide, titanium dioxide, or titania, with properties as photocatalysts.

Self-accumulation

The nanoparticles shall create a hexagonal fine-packed structure through the action of transverse capillary forces, etc.

Specified quantity

Designated quantity of hazardous materials under the Fire Service Act is the basic quantity for the regulation of hazardous materials, and is the quantity specified by a Cabinet Order for each rank of hazardous materials.

Silane Coupling Agents

An organosilicon compound that has both organic functional groups and hydrolyzable groups in a single molecule. Each of these groups chemically bonds to organic and inorganic materials, thereby firmly linking materials with different chemical properties.

Silica nanoparticles

A type of particle used during particle alignment by dip coating.

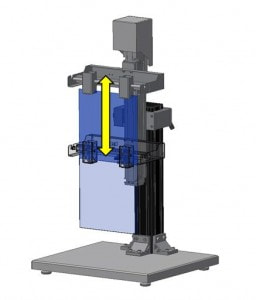

Stroke

The vertical movement distance of the dip coater. It is often adjusted to the shorter side of the object to be coated.

Spin coater

Equipment that coats a thin film by centrifugal force by dropping droplets onto a workpiece on a flat plate rotated at high speed.

Spray coater

Equipment that sprays coating liquid onto a workpiece and coats it. Coating of three-dimensional objects is possible, but there is a lot of loss of coating liquid.

Slurry

A mixture of solids and liquids. The properties of the slurry depend on the properties of the constituent liquids and particles, and the concentration of particles in the liquid.

Shear speed

The rate at which strain is applied. Also called "shear rate" or "velocity gradient".

Contact angle

When a drop of liquid is dropped onto a solid surface, the liquid becomes round due to its own "surface tension. The angle θ between the tangent line of the droplet and the solid surface is called the "contact angle.

Teflon

A fluoropolymer that is chemically stable and has excellent heat and chemical resistance. A trade name for polytetrafluoroethylene (PTFE). Dip coating equipment sometimes coats tanks, pipes, and other locations requiring acid resistance, but it is expensive.

Nanoimprint Lithography、NiL

Nanoimprint Lithography is a mass production technology for fine patterns proposed by Professor Stephen Y. Chou et al. of Princeton University (then University of Minnesota) in 1995. This technology realizes microfabrication by pressing an original plate (precision mold) onto a substrate. Compared to conventional exposure systems, this technology does not require a light source or lenses and is expected to enable mass production of nano-order patterns at low cost due to the simplicity of the equipment.

Wettability

Wettability is determined by the surface tension of the liquid and solid and the contact area of the liquid and solid. In dip coating, it is necessary to improve wettability by surface modification of the workpiece.

Hot air drying

Drying method in which air heated by a sheathed heater, etc. is sent to the workpiece surface after dipping, which takes longer than UV drying. In the case of coatings containing solvents, thermal efficiency is lower because hot air is not circulated and drying is done in a full one-pass process.

Hard Coat/Hard Coating

A method to protect the surface of a material from scratches by covering the surface of the material with a film, such as resin, which is vulnerable to scratches. Compared to glass and metal, polycarbonate and other materials have lower scratch resistance, so hard coatings are applied to make them less vulnerable to scratches.

Binder

bonding agent

Water Repellent Coating

Coating to prevent water droplet adhesion.

Oil Repellent coating

Coating to prevent fingerprints and other oil adhesion.

Photocatalysts

A generic term for substances that exhibit catalytic activity when irradiated by light. A typical material is titanium dioxide (TiO2). It is sometimes supported on other materials by dipping.

Surface modification

To improve the wettability of the surface of resins and other materials with low wettability and adhesiveness by UV irradiation, excimer irradiation, plasma irradiation, or other means.

Surface tension

Molecules on the surface have higher energy than those in the interior (bulk) because they cannot bind to other molecules. This higher free energy per unit surface area is expressed in terms of the free energy per unit surface area.

Pinning effect

When the surface of a solid has an angular bend, a droplet approaching it will not be able to proceed beyond that point.

Van der Waals force

A general term for the cohesive force that acts primarily between atoms and molecules that are neutral and have no electric charge.

Photoresists

A photosensitive material used in photolithography, sometimes with dipping for PCB patterns.

Polycarbonate:PC

A type of thermoplastic. It exhibits high transparency, impact resistance, heat resistance, and flame retardance.

Meniscus

It is the bending of the liquid surface that is formed by the interaction with the workpiece surface during workpiece withdrawal.

Cross hair tube force

A force between objects dispersed at an interface or in a film that acts in a direction parallel to the interface via surface tension.

Mold release agent

A chemical agent used in the pressing process to smoothly remove materials from the mold. By applying mold release treatment to precision molds (molds), continuous transfer, high-speed transfer, etc. become possible. There are many examples of applications, such as optical components (macro lenses, diffraction gratings, optical waveguides, etc.) and patterned media (e.g., HD).

Particle Array

The process of creating a hexagonal fine-packed structure on the surface of a workpiece by lateral capillary forces between nanoparticles by pulling glass and other materials from a liquid bath in which nanoparticles are dispersed at a very low speed in a dip coating system.

Hexagonal best-fit structure

A type of crystal structure. It is formed when particles are arranged by the advection-accumulation method.

Roll to roll

A method of continuously dipping rolled workpieces by dipping in the middle, drying, and winding.

Loader

A unit that feeds workpieces into a dip coater. ⇔ Unloader

Glass Transition Temperature

The temperature at which glass transition occurs in an amorphous solid material.

Jig

A part that holds a dip-coating object. Clip-shaped and other types are available.

Defect

A defect during particle alignment.

Dipcoater

Equipment for dip coating. There are devices that have a simple up-and-down mechanism only, those that can be programmed with pull-up points and up-and-down patterns, and those that have other additional functions such as front and rear functions. Also called dipping equipment or dip coating equipment.

Dipcoating

Equipment for forming films by dipping the coated object into the coating solution and then pulling it out. It is sometimes called dipping or impregnation method. Coating of not only flat plates but also three-dimensional objects is possible.

Dry washing

A cleaning method that removes organic matter by UV irradiation or plasma without using a cleaning solution.

Dry Processes

A method of depositing a film in a vacuum. Evaporation, sputtering, etc. ⇔ Wet process

Newtonian fluid

A Newtonian fluid is a fluid whose viscosity does not change with shear rate. Examples are water and oil. On the other hand, non-Newtonian fluids change viscosity with shear rate. Examples are cream and mayonnaise. Generally, Newtonian fluids are suitable for dip coating.

Bar coater

Equipment that coats a flat workpiece by dropping a coating liquid onto the workpiece and then moving a squeegee with an adjusted gap back and forth.

Viton

Viton, a trademark of E.I. du Pont de Nemours and Company, is a fluoroelastomer. It has higher chemical resistance than PP.